low noise air compressor

Air compressors are equipment used to compress air. In order to let more friends understand the related issues of air compressors, here I will give you a popular science.

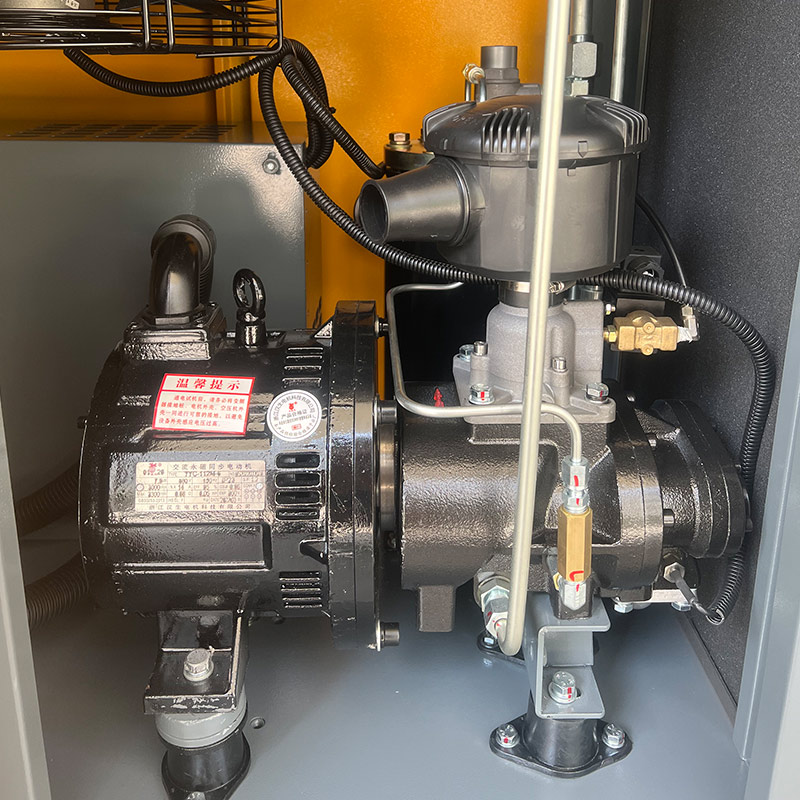

An air compressor is similar in structure to a water pump and is a device used to compress gas. Most air compressors use reciprocating pistons, rotating vanes or screws.

When the air compressor is working, the airflow is inhaled by the self-cleaning air filter and automatically cleaned by the PLC. After the automatic adjustment of the intake guide vane, it enters the first stage of compression. The temperature of the gas after the first stage of compression is compared with High, into the second stage cooling unit. In order to prevent the gas in the system from being poured into the compression chamber, a suspension full-open check valve is installed on the exhaust pipe of the compressor. The gas discharged from the compressor is pushed from the check valve to the exhaust muffler, and then flows into the first Level, second level, third level, and finally enter the main exhaust gas road.

Two: the characteristics of the air compressor The air compressor is directly driven by the motor, which drives the crankshaft to rotate, and the connecting rod drives the piston to reciprocate to change the volume of the cylinder. Due to the change of the pressure in the cylinder, the air enters the cylinder through the intake valve through the air filter, and due to the reduction of the cylinder volume in the compression stroke, the compressed air enters the air storage tank through the exhaust pipe and check valve through the exhaust valve. When the exhaust pressure reaches 0.7 MPa, the pressure switch control is automatically closed. The pressure switch starts automatically when the pressure of the gas storage tank drops to 0.5-0.6 MPa.

The air compressor is the core equipment of the pneumatic system and the main body of the electromechanical induced air source device. It converts the mechanical energy of the prime mover into air pressure energy and is the air pressure generator for compressed air.

Three: The use of air compressor Depending on the type, the air compressor has a wide range of uses, and can be used in the power industry, chemical fiber industry, pharmaceutical industry and other fields. Specifically, here I will briefly explain it to you. Power industry: For example, the ash removal system in the power industry, the compressed air system for factories, and the water treatment system include boiler water treatment systems and industrial wastewater treatment systems. Chemical fiber industry: The cotton spinning industry mainly uses clean compressed air as the power source; the chemical fiber industry mainly uses instrument gas and suction gun gas, and the printing and dyeing gas is mainly used for power instruments. Pharmaceutical industry: The non-contact type is mainly used for power execution and instrumentation. Because direct contact requires a large amount of air and requires stable air quality, the centrifugal type is generally used. Of course, it can also be applied to food, mining, textile, transportation and many other industrial fields, so the air compressor is also called "general machinery".